There are many ways to build electric motors, we'll evaluate them here.

What do we think is the best compromise to keep motors easily scalable to different sizes while the manufacturing costs are still reasonable?

What are compromises we don't make since we think it will harm longevity and efficiency?

The cooling is one of the very important aspects of electric motors. So we'll adapt the housing to these needs. Cooling fins and liquid cooling channels are possible options.

Check out our first, rough concept model on Grabcad. Click on "3D" to see it in 3 dimensions and navigate through it.

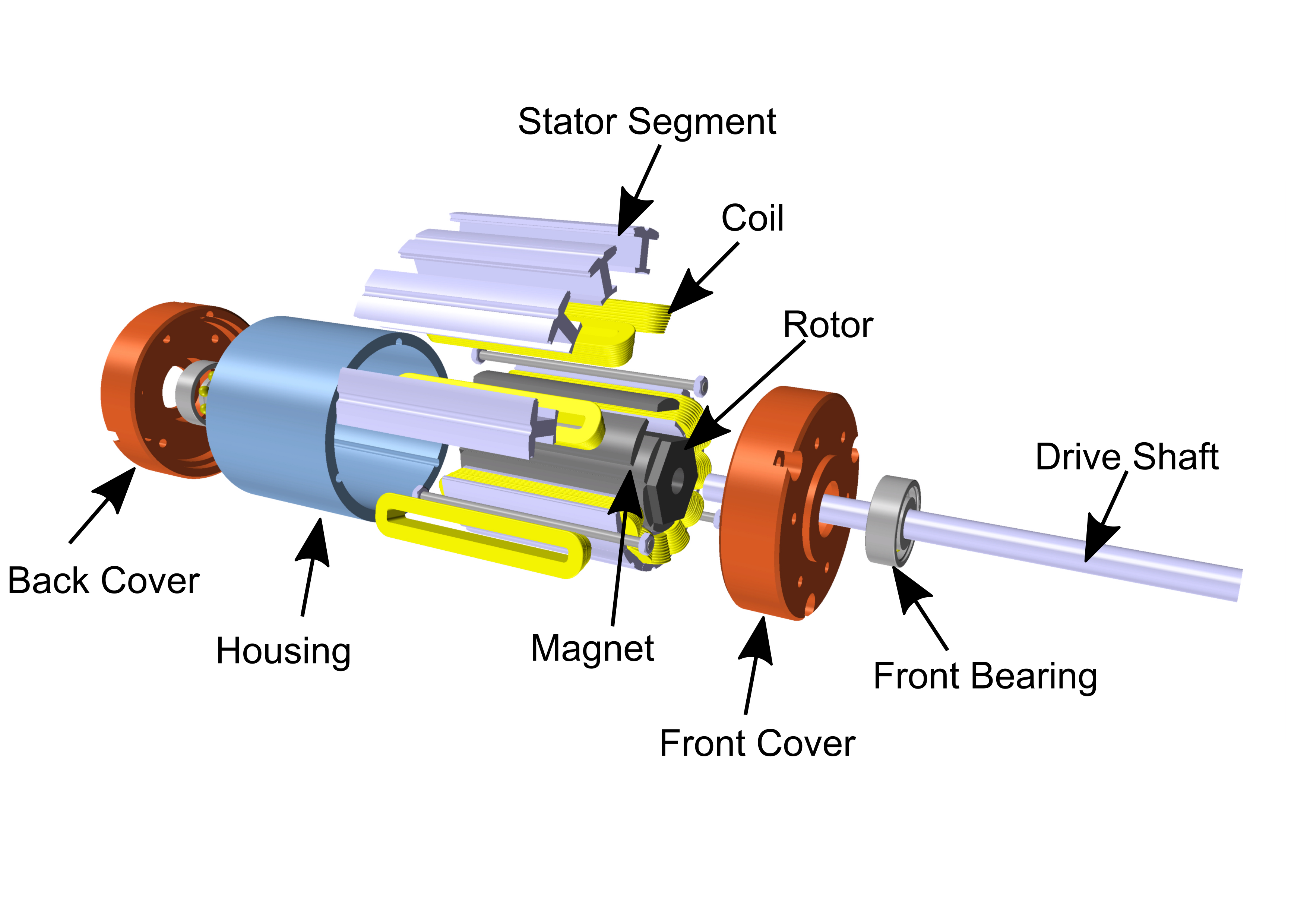

Here we show you a rendering with the basic parts of a motor.

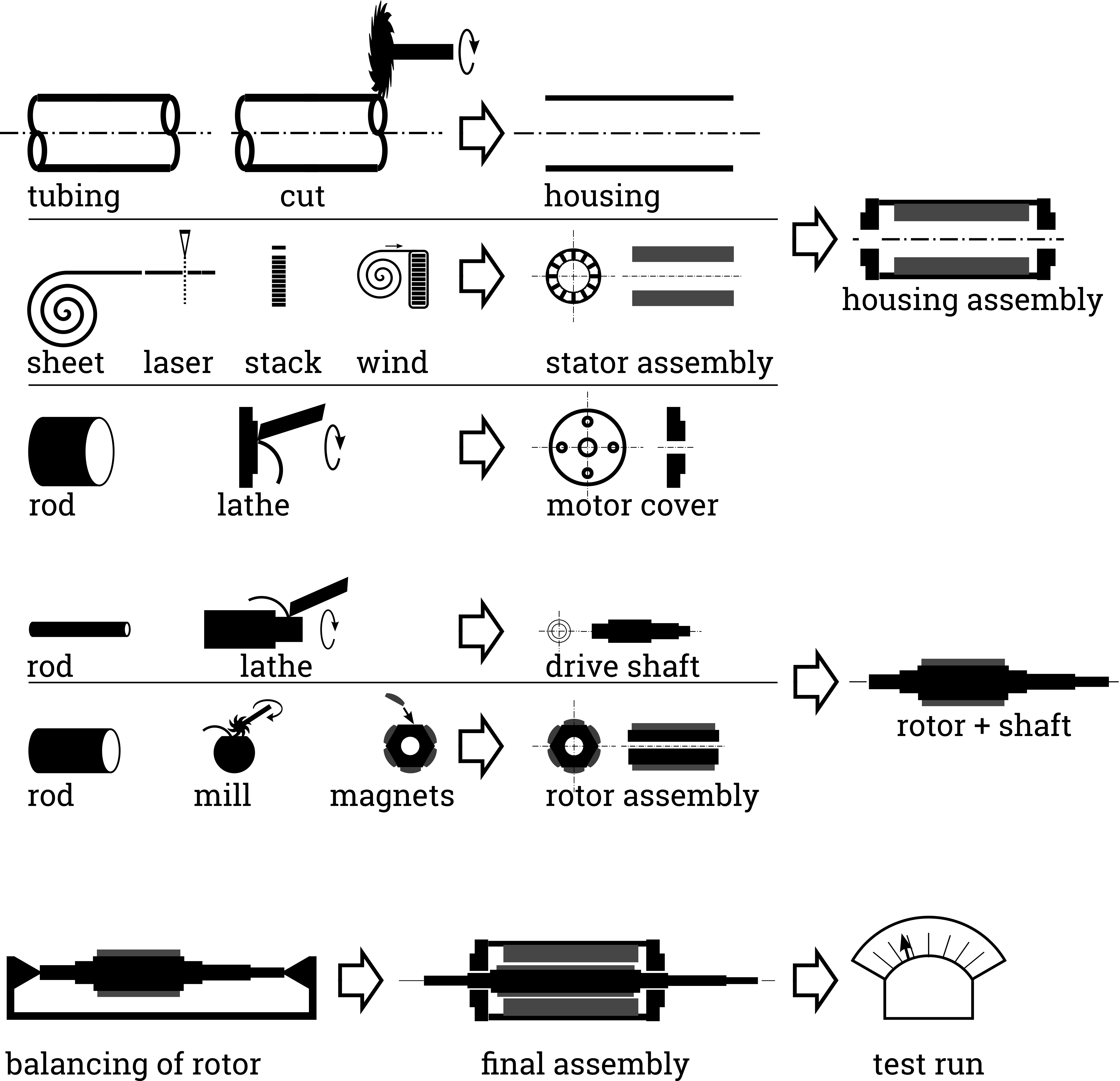

We also have visualised the manufacturing process of our motors. As you can see these are relatively simple steps that can be automated with a high variability except for one: The punching needs special cutting dies for each rotor diameter and pole count. But since we have a segmented stator these cutting dies will be relatively small so the cost for having these in stock will be reasonable.